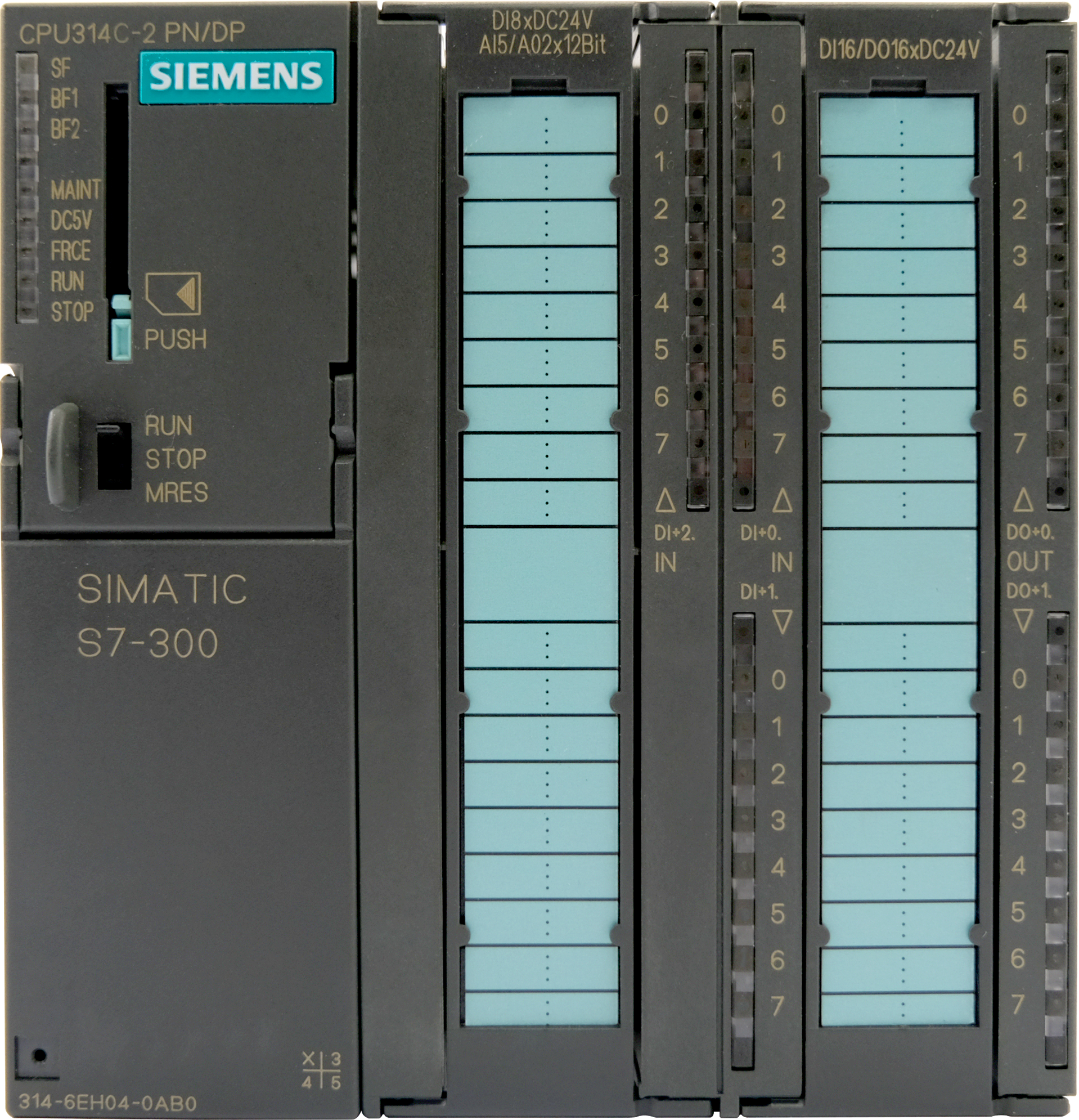

plc module

A PLC (Programmable Logic Controller) module serves as the central processing unit in industrial automation systems, combining robust hardware with sophisticated control capabilities. This essential component executes programmed instructions to manage manufacturing processes, equipment operations, and production lines with precision and reliability. The module features digital and analog I/O interfaces, enabling seamless communication with various sensors, actuators, and other industrial devices. Modern PLC modules incorporate advanced features such as high-speed processing, built-in networking capabilities, and modular expansion options to accommodate growing system requirements. They support multiple programming languages, including ladder logic, structured text, and function block diagrams, making them accessible to technicians with varying levels of expertise. The module's design prioritizes industrial-grade durability, with components rated for extended operation in harsh environments, including exposure to extreme temperatures, vibration, and electromagnetic interference. These modules excel in real-time control applications, offering microsecond-level response times and deterministic operation crucial for precision manufacturing and process control.