delta industrial automation

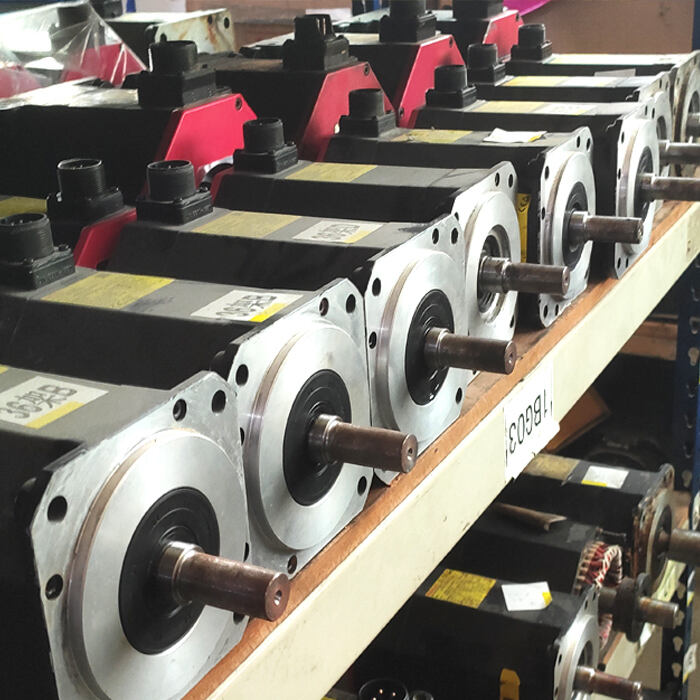

Delta industrial automation represents a comprehensive suite of advanced technological solutions designed to revolutionize manufacturing and production processes. This cutting-edge system integrates sophisticated control systems, robotics, and smart sensors to create seamless automated operations. At its core, Delta automation encompasses programmable logic controllers (PLCs), human-machine interfaces (HMIs), servo systems, and motion controls that work in perfect synchronization. The system excels in precision control, offering microsecond-level response times and advanced motion control capabilities that ensure exceptional accuracy in manufacturing processes. Its networking capabilities enable seamless integration with existing industrial protocols, supporting both traditional and Industry 4.0 applications. Delta's automation solutions are particularly notable for their scalability, allowing businesses to start with basic automation needs and expand as requirements grow. The system supports various industrial applications, from simple assembly lines to complex manufacturing processes, including packaging, material handling, and precision machining. With built-in diagnostic features and predictive maintenance capabilities, the system helps minimize downtime and optimize operational efficiency. The platform also incorporates energy management functions, helping facilities reduce power consumption while maintaining optimal performance levels.