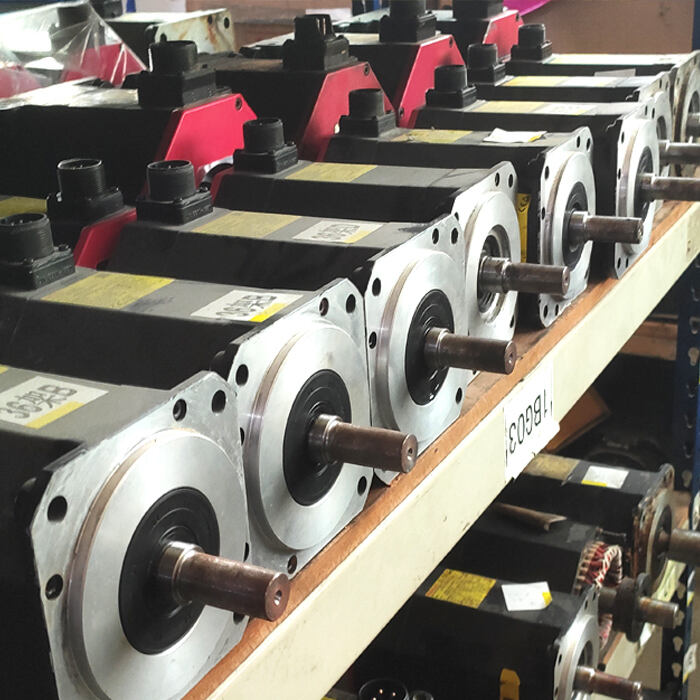

encoder motor servo

An encoder motor servo represents a sophisticated integration of precision control and feedback mechanisms, combining the functionality of an electric motor with high-accuracy position sensing capabilities. This advanced system consists of three main components: a DC or AC motor, an encoder for position and speed feedback, and a sophisticated control circuit. The encoder continuously monitors the motor's shaft position and rotation speed, sending this data to the control system, which then makes precise adjustments to maintain desired performance parameters. The system operates on a closed-loop principle, where real-time feedback ensures exact positioning and movement control. These devices excel in applications requiring precise motion control, such as industrial automation, robotics, and CNC machinery. The encoder motor servo's ability to maintain accurate position control while adapting to changing loads and conditions makes it invaluable in modern manufacturing processes. Its sophisticated design allows for rapid acceleration and deceleration while maintaining positional accuracy to within fractions of a degree. This level of precision, combined with reliable performance and longevity, makes encoder motor servos essential components in high-precision manufacturing equipment, automated assembly lines, and advanced robotics applications.