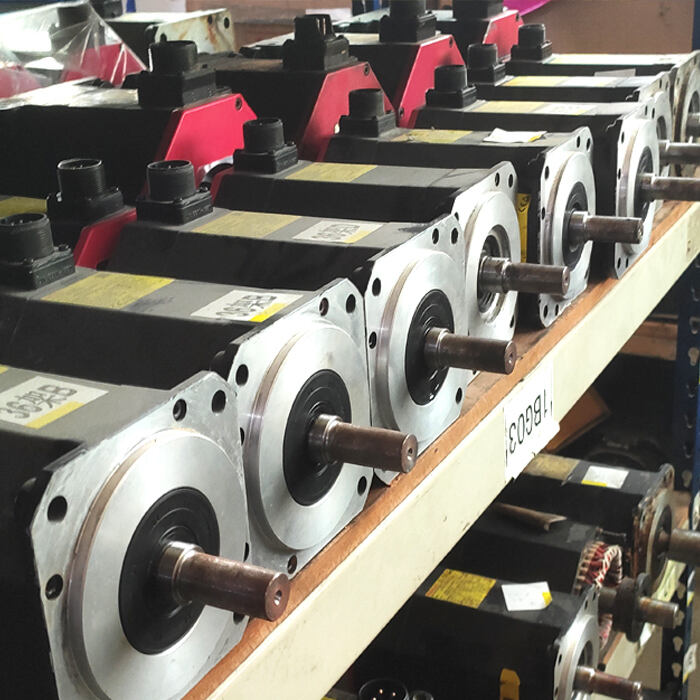

servo encoder

A servo encoder is a sophisticated motion control device that plays a crucial role in providing accurate position feedback in automated systems. This precision instrument combines advanced sensing technology with robust mechanical design to convert rotary or linear motion into digital signals. At its core, the servo encoder continuously monitors the position, speed, and direction of a motor or mechanical system, enabling precise control and positioning. The device operates by utilizing either optical, magnetic, or capacitive sensing methods to generate electrical pulses that correspond to mechanical movement. These pulses are then processed to determine exact position and movement parameters. In industrial applications, servo encoders are essential components in CNC machines, robotics, and automated manufacturing systems, where they ensure precise movement control and positioning accuracy. The technology also finds extensive use in modern electronics, such as computer peripherals, surveillance cameras, and automated door systems. With resolutions ranging from simple incremental feedback to highly precise absolute positioning, servo encoders provide the foundation for reliable motion control in both industrial and consumer applications.