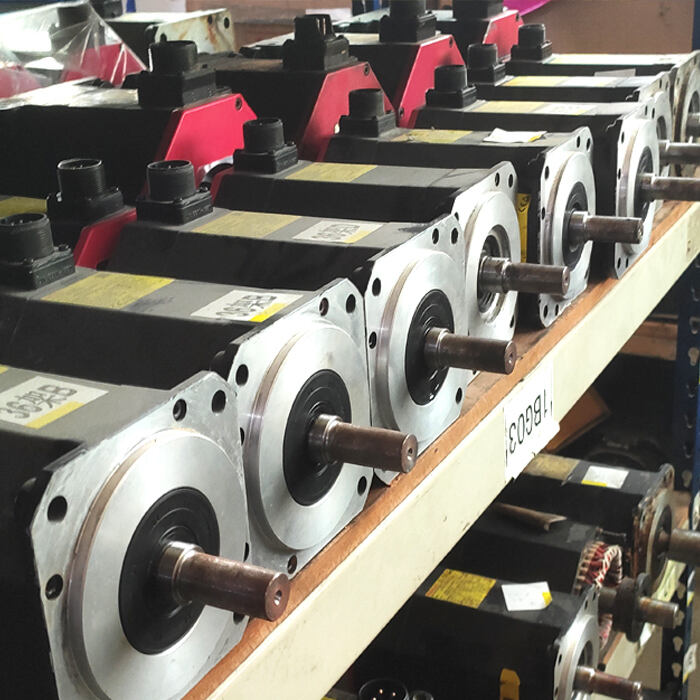

ac servo motor

An AC servo motor represents a sophisticated electromechanical system that delivers precise control over position, velocity, and torque in various industrial applications. This advanced motor system consists of a motor, encoder, and driver working in harmony to provide exceptional accuracy and responsiveness. The motor operates on alternating current and incorporates feedback mechanisms that continuously monitor and adjust its performance. With its ability to maintain exact positioning and smooth rotation across different speeds, the AC servo motor excels in applications requiring high precision and dynamic response. The system's core functionality revolves around its closed-loop control system, which utilizes encoder feedback to ensure precise movement and positioning. Modern AC servo motors feature advanced digital controls, enabling seamless integration with automation systems and programmable logic controllers. These motors can achieve rapid acceleration and deceleration while maintaining precise control, making them ideal for robotics, CNC machines, and automated manufacturing processes. Their compact design and high power density allow for efficient space utilization in industrial settings, while their robust construction ensures reliable operation under demanding conditions.