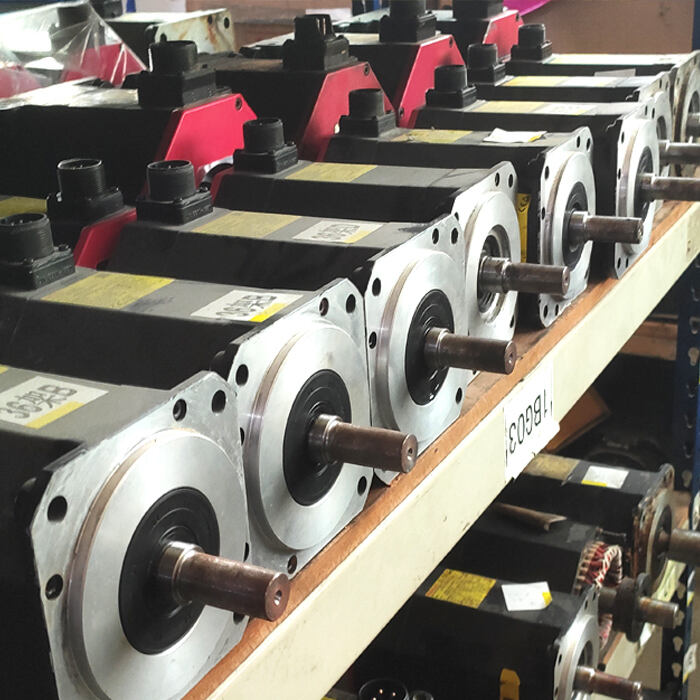

industrial servo motor

Industrial servo motors are sophisticated electromechanical devices that provide precise control of position, velocity, and acceleration in automated systems. These motors operate through a closed-loop feedback system that continuously monitors and adjusts motor performance to maintain desired parameters. The motor consists of several key components including a motor unit, encoder, drive, and controller that work in harmony to deliver accurate motion control. What sets industrial servo motors apart is their ability to respond instantly to changes in load or command signals, making them ideal for applications requiring dynamic performance and positioning accuracy down to fractions of a millimeter. They excel in high-speed operations while maintaining exceptional torque control throughout their speed range. Modern industrial servo motors incorporate advanced features such as digital communication protocols, built-in safety functions, and energy-efficient design principles. These motors find extensive applications across various industries, from CNC machines and robotics to packaging equipment and precision assembly lines. Their compact size relative to their power output, combined with their reliability and maintainability, makes them a cornerstone of industrial automation.