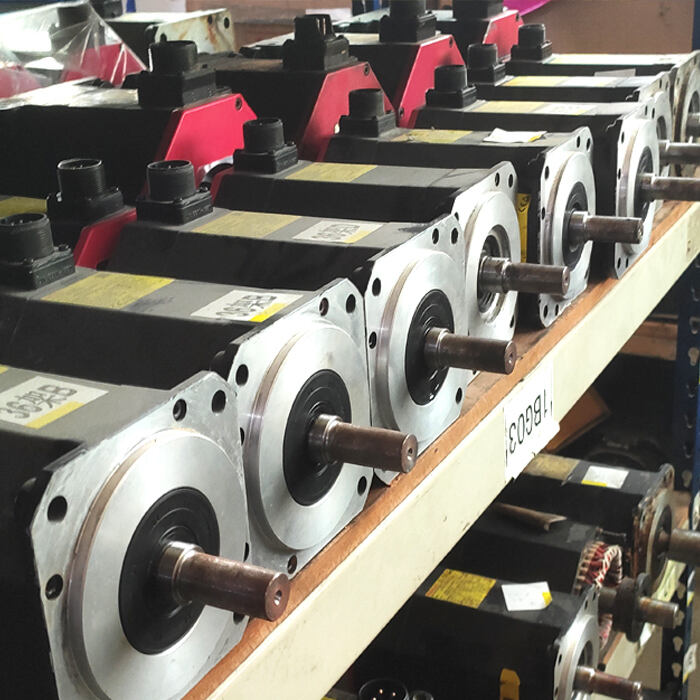

servo motor drive

A servo motor drive is an advanced electronic control system that precisely regulates the position, velocity, and torque of servo motors. This sophisticated device converts power input into highly controlled motion output, enabling precise automation across various industrial applications. The drive system comprises multiple components including a controller unit, power module, feedback mechanisms, and advanced algorithms that work in harmony to deliver exceptional motion control. It interprets command signals and provides the exact amount of power needed to achieve desired motor performance, while continuously monitoring and adjusting parameters in real-time. Modern servo drives incorporate features such as auto-tuning capabilities, multiple control modes, built-in protection functions, and network connectivity options. They excel in applications requiring accurate positioning, smooth motion profiles, and rapid response times, making them essential in robotics, CNC machines, packaging equipment, and precision manufacturing processes. The drive's ability to maintain optimal performance under varying loads and speeds, combined with its energy-efficient operation, makes it a cornerstone of modern industrial automation systems.