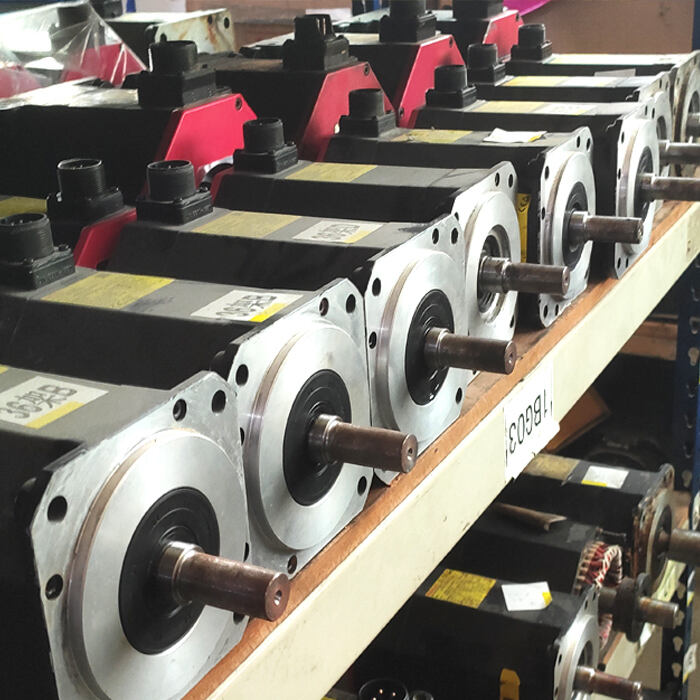

servo motors and drives

Servo motors and drives represent a sophisticated motion control system that combines precision engineering with advanced control technology. These systems consist of a motor, drive, encoder, and control circuit working in harmony to deliver accurate position, velocity, and torque control. The motor component converts electrical energy into mechanical motion, while the drive acts as the command center, processing feedback signals and adjusting output parameters in real-time. Operating on a closed-loop feedback principle, servo systems continuously monitor their position and velocity, making instantaneous corrections to maintain desired performance parameters. These systems excel in applications requiring precise movement control, from industrial robotics to CNC machinery. Modern servo motors and drives incorporate advanced features such as digital communication protocols, auto-tuning capabilities, and programmable motion profiles. They offer exceptional response times, typically in milliseconds, and can achieve positioning accuracy down to micrometers. The systems are scalable, ranging from small precision instruments to large industrial machinery, and can operate at various speeds while maintaining consistent torque output. Their energy efficiency and reliability make them ideal for continuous operation in demanding industrial environments.