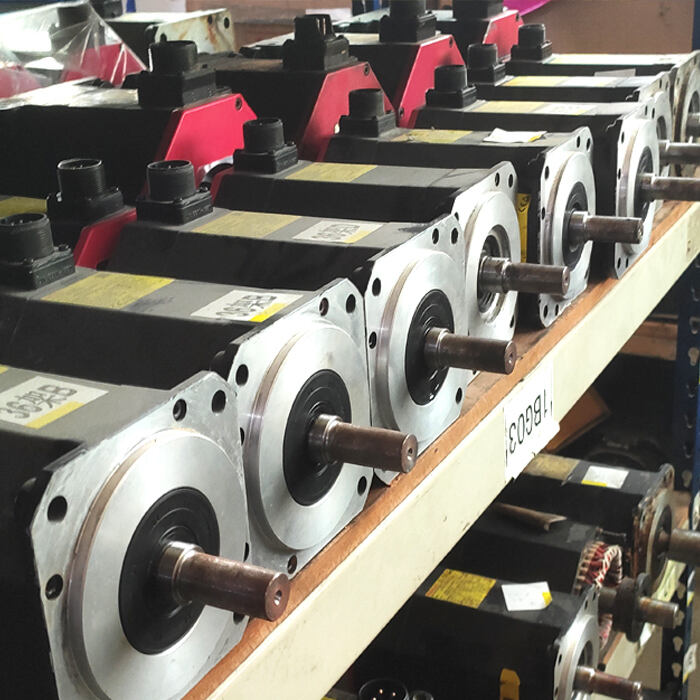

ac servo

The AC servo is a sophisticated motion control system that combines precision engineering with advanced electronic control capabilities. This system consists of an AC servo motor, a drive unit, and a controller that work in harmony to deliver precise positioning, speed control, and torque regulation. At its core, the AC servo utilizes a closed-loop feedback mechanism that constantly monitors and adjusts motor performance to maintain optimal operation. The system employs encoders or resolvers to provide real-time position and velocity feedback, enabling exceptional accuracy in motion control applications. The technology incorporates advanced features such as auto-tuning capabilities, multiple control modes, and comprehensive diagnostic functions. AC servos are widely implemented across various industries, from manufacturing automation and robotics to packaging equipment and CNC machinery. They excel in applications requiring rapid acceleration, deceleration, and precise positioning, making them invaluable in modern industrial processes. The system's ability to maintain consistent performance under varying loads and speeds, coupled with its energy efficiency and minimal maintenance requirements, has established it as a cornerstone of industrial automation technology.