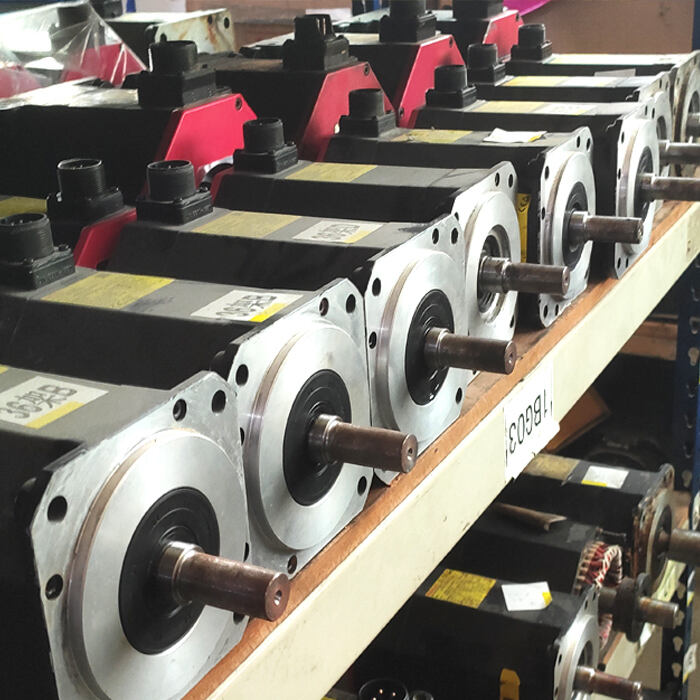

servo motor in cnc

A servo motor in CNC (Computer Numerical Control) systems represents a sophisticated electromechanical device that serves as the cornerstone of precise motion control. This advanced motor system combines powerful mechanical operation with intelligent feedback mechanisms to deliver exact positioning, velocity control, and acceleration in automated machinery. At its core, the servo motor utilizes a closed-loop control system that continuously monitors and adjusts its position through encoder feedback. This system enables the motor to maintain exceptional accuracy even under varying load conditions. The technology incorporates both a motor unit and an encoder that works together with a sophisticated controller, allowing for real-time position monitoring and instant adjustments. In CNC applications, servo motors excel in controlling axis movements, enabling the precise coordination required for complex machining operations. These motors can smoothly transition between different speeds and positions, making them ideal for applications requiring variable speed control and precise positioning. They offer outstanding torque characteristics at both low and high speeds, ensuring consistent performance across various operating conditions. The implementation of servo motors in CNC systems has revolutionized manufacturing processes by enabling higher precision, improved efficiency, and enhanced productivity in automated operations.