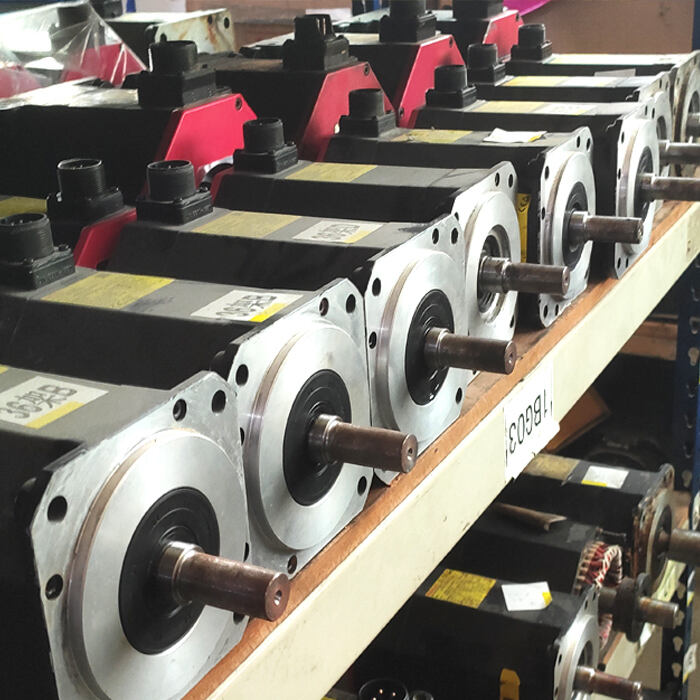

ac servo drive

An AC servo drive is a sophisticated electronic control system that precisely regulates the position, velocity, and torque of AC servo motors. This advanced motion control device converts input commands into precisely controlled electrical signals that drive the motor with exceptional accuracy. Operating through closed-loop feedback mechanisms, the AC servo drive continuously monitors and adjusts motor performance in real-time, ensuring optimal operation under varying load conditions. The drive system incorporates advanced digital signal processing technology to maintain precise control over motor parameters, including speed, position, and torque. It features multiple control modes, including position control, speed control, and torque control, making it incredibly versatile for various industrial applications. The system's high-resolution encoder feedback enables precise positioning capabilities down to microscopic levels, while its advanced algorithms provide smooth acceleration and deceleration profiles. Modern AC servo drives also include built-in protection features against overcurrent, overvoltage, and overheating, ensuring reliable operation and extended equipment life.