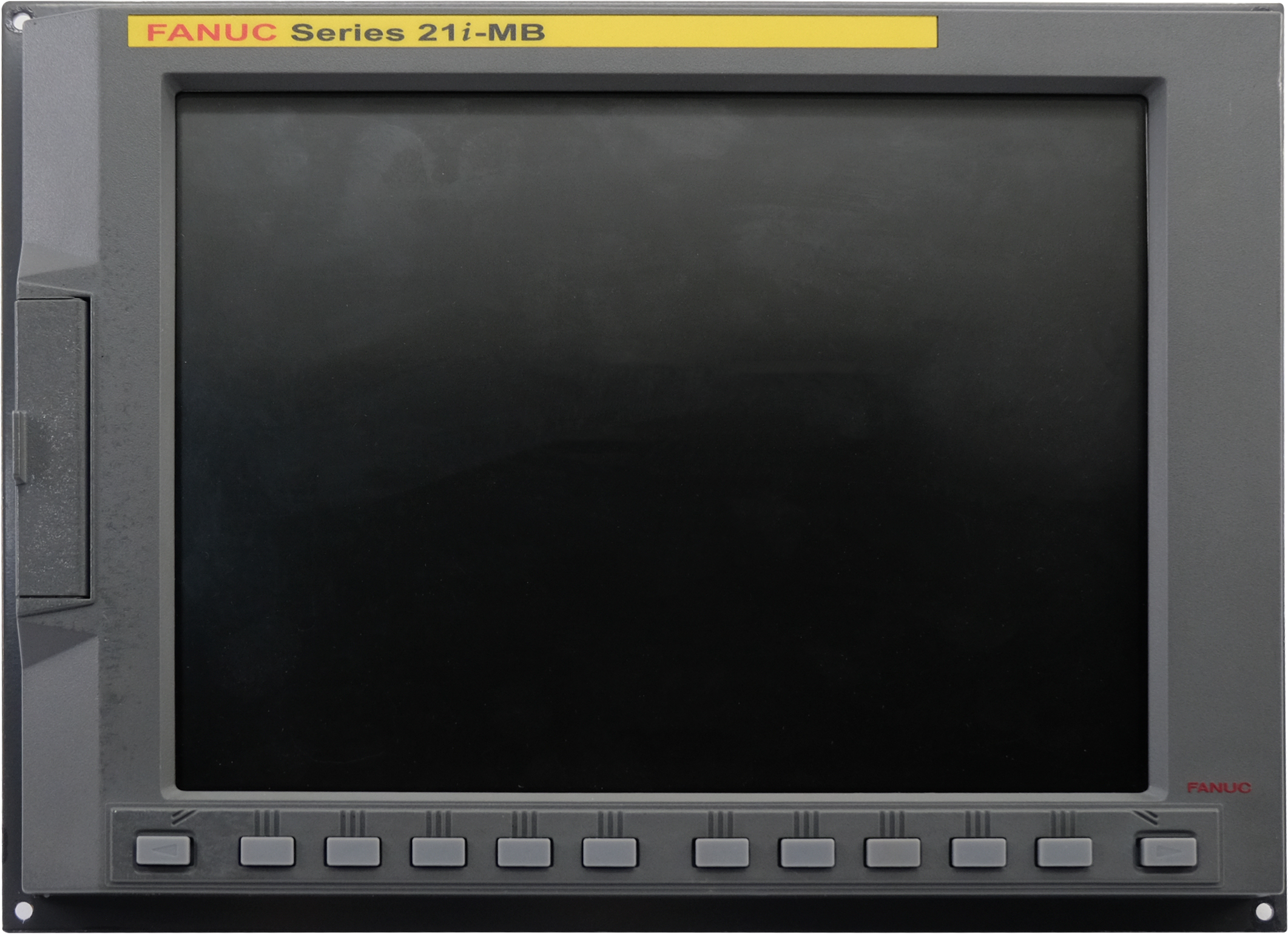

servo drive system

A servo drive system represents a sophisticated motion control solution that integrates precision positioning with dynamic performance capabilities. This advanced system consists of a servo motor, drive controller, and feedback mechanisms working in harmony to deliver accurate, repeatable motion control. The system operates on a closed-loop principle, continuously monitoring and adjusting motor position, speed, and torque to maintain desired performance parameters. At its core, the servo drive system utilizes real-time feedback from encoders or resolvers to compare actual position with commanded position, making instantaneous corrections to achieve optimal movement precision. This technology finds extensive applications across various industries, from manufacturing automation and robotics to packaging equipment and CNC machinery. The system excels in applications requiring precise positioning, velocity control, and rapid response times. Modern servo drive systems incorporate advanced features such as auto-tuning capabilities, multiple control modes, and network connectivity options, making them highly adaptable to diverse industrial requirements. The integration of digital control algorithms and sophisticated power electronics enables these systems to deliver superior dynamic performance while maintaining energy efficiency.